Carbon Footprint: Marfran measures the environmental impact of its TPE

- Home

- Innovazione

- Carbon Footprint: Marfran measures the environmental impact of its TPEs

Marfran is increasingly active in supporting a sustainable, circular and green market. In recent years, the company based in Brescia has added, step by step, a piece to the process of improving the environmental performance of its TPEs. For this reason, with the aim of combating climate change, it has successfully engaged in the formulation of new compounds with reduced climate-altering impact by validating them through the measurement of the Carbon Footprint of each product.

As already known, everything that is produced and placed on market causes climate-changing greenhouse gas emissions. The Carbon Footprint tool turns out to be the most advanced and effective tool for estimating the amount of gases generated through the production of each individual product, from a service, from an organization or from an event. This is expressed in kilos of CO₂ equivalent and it is supported by objective datas, which are shared internationally.

The assessment carried out by Marfran considered the impact caused by the numerous climate-altering emissions deriving from the products analyzed, adopting a life cycle approach. It focuses on the study of the activities in the so-called “Cradle to Gate” perimeter, starting from the raw material extraction phase, up to the moment in which the product leaves the company headquarters and is finally distributed to customers.

Specifically in the analysis, Marfran measured the amount of greenhouse gas emissions related to their TPEs. For each individual family analyzed, the company calculated the amount of CO₂ emitted in relation to the different phases of the product’s life cycle. As for the materials analyzed, the product categories Shore A and Shore D were chosen and used as standard materials during the measurement. It calculates the quantity of greenhouse gas emissions that have been saved whether, instead of the standard material, people use the formulations specifically developed by Marfran.

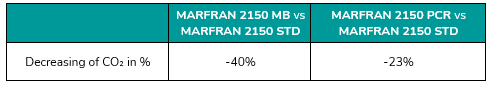

Below there is a concrete example of Carbon Footprint calculation and the results that have been recorded by the company to better illustrate the concept. It shows the reduction in percentage of CO₂ equivalent obtained using the alternative “Mass Balance” (MB) and PCR materials compared to the reference standard MARFRAN 2150:

The reduction of greenhouse gases that are emitted can reach around -40% in the case of the MB materials while, they would reach -23% in the case of the PCR with the standard material compared to the standard used.

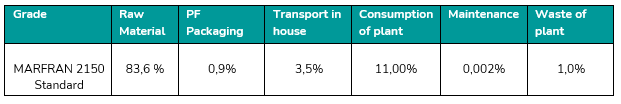

Furthermore, as part of the analysis, the percentages related to the quantity of carbon dioxide produced during the individual life phases of its TPE were analyzed in order to understand which phase had the greatest impact, in terms of climate-altering gas emissions, between the procurement of raw materials, packaging, transport, production, maintenance and the waste generated. The table below shows the result emerged from the calculation made using the standard MARFRAN 2150 materials:

Observing the table, it is possible to better understand the distribution of the quantity as a percentage of emissions produced by the standard material with respect to the single phases of its life cycle. Analysing the data, emerged that 83.6% of the emissions derive from the extraction and treatment of raw materials, 0.9% from packaging, 3.5% from upstream transport, 11% from consumption generated within the plant, 0.002% from maintenance and, finally, 1% from the waste production.

The phase with the greatest climate impact is the one linked to the extraction and treatment of raw materials. In fact, this trend has been recorded on all Carbon Footprint calculations performed up to now. This demonstrates that, since the phases of the production process are identical, the difference in terms of emissions is due to the raw material we chose.

Tags: CO2 EQUIVALENT, MASS BALNCE